India Energy Week 2025: Hydrogen and Renewables in the Limelight

India Energy Week was held at Yashobhoomi Convention Centre, New Delhi, from 11th to 14th February 2025. It was the first major energy event of 2025, with over 70,000 visitors and over 700 exhibitors. The theme of the event was ‘Energy Transition & Green Future’.

The event was held under the patronage of Ministry of Petroleum and Natural Gas (MoPNG), and was organised by Federation of Indian Petroleum Industry (FIPI). Oil and Natural Gas Corporation (ONGC) was the principal partner of the event.

Hydrogen and Renewables Hot Topics at IEW 2025

While interacting with exhibitors and visitors at IEW 2025, it was evident that Green Hydrogen and Renewable Energy (RE) were the most talked about topics at the event. Several exhibitors, including those from India as well as overseas, displayed their offerings in these segments such as electrolysers, Hydrogen fuel cells, Battery Energy Storage Systems (BESS), Ethanol solutions, solar modules, and more.

GAIL Displays Cost-Effective H2 Fuel Cell Prototype

Gas Authority of India Ltd. (GAIL), which was also one of the partners of the event, displayed the prototype of a 1 KW Hydrogen fuel cell, which was developed by GAIL in collaboration with IndianOil Corporation (IOCL), Centre for High Technology (CHT) and High Energy Batteries (India) Ltd. This fuel cell featured reduced use of Platinum catalyst, thus increasing its cost effectiveness. While a typical H2 fuel cell uses 0.3 to 0.5 mg of Pt-catalyst per sq.cm, GAIL’s H2 fuel cell uses 0.2 mg/sq.cm of the Pt-catalyst. Moreover, in order to increase efficiency, this cell features a unique flow pattern for Hydrogen over the Pt-catalyst. This innovative flow pattern reduces the amount of Pt-catalyst required.

While speaking to CableCommunity, GAIL representatives mentioned that this fuel cell can be scaled up to 2.4 KW, which can be installed in 3-wheeler Hydrogen Fuel Cell Electric Vehicles (HCEVs).

Jackson Green Displays Infinity Range of Electrolysers, Green Methanol Solution

Full In-House Electrolyser Manufacturing

Jakson Green, a major Renewable Energy and Green Hydrogen equipment manufacturer, displayed its range of Infinity alkaline electrolysers at IEW 2025. Representatives at Jakson Green shared that the company’s manufacturing unit is situated in Noida sector-80, and has an annual manufacturing capacity of 300 MW. They highlighted the fact that unlike many other electrolyser manufacturers, which import individual components and then assemble the electrolyser stack in India, Jakson Green has full in-house manufacturing capability at Noida. These scalable electrolysers produce 99.99% pure Hydrogen, and this purity can be increased to 99.999% if required by the client.

Jackson Green: World’s First CO2 to Methanol Plants Being Deployed for NTPC

Jakson Green also displayed a model of its 10 Tonne Per Day (TPD) Carbon dioxide to Methanol synthesis plant, which is currently being developed at NTPC’s Vindhyachal Thermal Power Plant in Singrauli, MP. As per the company, this is the world’s first such project. Jakson Green’s technology captures Carbon dioxide from the flue gases of the TPP, which is then combined with Green Hydrogen generated in proximity to the TPP. These two gases are then fed to a reactor, where syn-gas (a mixture of Carbon monoxide and Hydrogen) is produced. This syn-gas can then be used to derive methanol. This project drew attention of several visitors at the event, and upon query, Jakson Green representatives shared that typically a 10 TPD CO2 to methanol plant would entail a cost estimate of about Rs. 400 crore.

L&T Energy Showcases its Range of Electrolysers at IEW 2025

L&T Energy exhibited its ‘McLyzer’ electrolysers at the India Energy Week 2025. These electrolysers feature a compact design with a footprint of under 45 Sq.metre per MW. McLyzer electrolyser stacks are capable of delivering 99.999% pure Hydrogen. L&T’s electrolysers are available as 0.5 or 1 MW stacks, which can be scaled to multi-MW clusters. These alkaline electrolysers are manufactured at L&T’s facility in Hazira, Gujarat, under license from France’s McPhy.

Reliance New Energy Displays HJT Solar Module, BESS Solutions

Reliance New Energy showcased its solar modules and BESS solutions at IEW 2024. Additionally, a VR tour of Reliance New Energy’s Jamnagar solar gigafactory was also offered to visitors at the company’s stall.

20 GW Solar Module Manufacturing by 2026-end

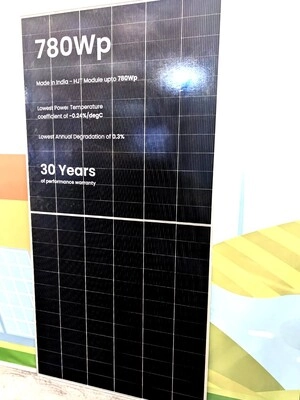

While speaking to CableCommunity, a Reliance New Energy representative shared that Reliance New Energy targets an annual solar module production capacity of 20 GW by December 2026. He added that in order to attain solar module manufacturing capability, the company had acquired REC Solar Holdings in October 2021. This enabled Reliance New Energy to manufacture Hetero Junction Technology (HJT) based solar modules, which offer lower performance degradation with rise in temperature (0.24%/degree Celsius) as compared to more prevalent TOPCon solar modules (0.3%/degree Celsius). In fact, the company showcased its 780 Wp HJT solar module at the tradeshow.

Reliance Displays Liquid-Cooled BESS at IEW 2025

Apart from its solar module, the company also showcased its liquid-cooled BESS, which is based on prismatic Lithium Iron Phosphate (LFP) cells. Notably, Reliance had acquired Netherland’s LithiumWerks in 2022. Upon interaction with CableCommunity, the company’s representative shared that as of now, manufacturing of Li-ion cells for these solutions is not being carried out in India, and that the company imports cells from LithiumWerks’ manufacturing facility which are then used in Reliance New Energy’s BESS solutions. Reliance New Energy expects that production of Lithium-ion cells will begin soon at Jamnagar.

Challenges of Hydrogen Transportation a Burning Topic at IEW 2025

While interacting with representatives from Green Hydrogen solution provider companies, it was evident that the biggest un-answered question about Green H2 was tackling challenges in its transportation. Hydrogen’s low density and notorious flammability makes it hazardous to transport.

Representatives at OEG Offshore, a UK-based manufacturer of cryogenic tanks and offshore containers, mentioned that while cryogenic tanks are suitable for short-distance transportation of Hydrogen, it is dicey to transport the gas over long distances in this manner. Even then, cryogenic tanks for carrying Hydrogen need to be maintained at higher pressure, and are very expensive, making it unfeasable for small or medium sized Green Hydrogen producers. Most professionals at the event agreed that pipelines remain the safest way as of now to transport Green H2 over long distances. This discussion gains importance considering that only recently, Tata Steel became the first Indian company to produce Steel pipes suitable for Hydrogen transportation.

Essar Showcases LNG Truck & Logistics Solutions

Essar Group showcased an LNG-based truck at the India Energy Week 2025. The truck has a fuel tank capacity of 930 litres and is manufactured by Blue Energy Motors, an Essar Group company.

Besides showcasing its LNG truck, Essar Group’s stand at the event featured services by Greenline Mobility Solutions, also a part of Essar Group. Greenline Mobility Solutions provides logistics support to its various clients, using vehicles manufactured by Blue Energy Motors.

Next Edition of IEW Planned in Goa

IEW 2026, will be held in February 2026 in ONGC-IPSHEM, Goa. The event is expected to grow, with the expected number of visitors to cross 75,000.